Introduction: The Foundation of a Professional Backpack’s Quality

When it comes to professional backpacks, quality isn’t just a luxury—it’s a necessity. A professional backpack serves multiple critical purposes: protecting valuable equipment like laptops and tablets, maintaining a polished appearance in business settings, and withstanding the rigors of daily commuting. At the heart of these functions lies one fundamental element: material quality.

Material quality forms the cornerstone of any professional backpack investment for several essential reasons:

• Durability: Quality materials withstand daily wear and tear, ensuring your backpack remains functional for years rather than months

• Protection: Superior materials provide better safeguards for expensive electronics and important documents

• Aesthetics: Premium materials maintain their appearance longer, preserving your professional image

• Value: Higher-quality materials justify the investment through extended usability and performance

The difference between quality materials and substandard ones is stark—high-quality professional backpacks typically last 5-7 years with proper care, while lower-quality options often need replacement within 12-18 months. This becomes particularly important considering the average professional carries between 11-15 pounds (5-7 kg) of equipment daily, placing significant stress on bag materials and construction.

In this comprehensive guide, we’ll explore the essential properties that define high-quality professional backpack materials, examine specific material types from premium nylons to full-grain leather, and provide practical guidance for selecting the perfect material for your professional needs. Understanding these elements will help you make an informed investment in a premium leather backpack for professionals that meets both functional requirements and aesthetic standards for executive leather backpacks for work.

Essential Properties of High-Quality Professional Backpack Materials

Durability Factors: Abrasion, Tear, and Burst Resistance

When evaluating professional backpack materials, three key durability factors determine how well the bag will withstand daily professional use:

Abrasion resistance refers to a material’s ability to withstand surface wear from repeated friction. This property is crucial for areas that constantly rub against clothing, desks, car seats, or other surfaces. Professional backpacks with poor abrasion resistance develop worn patches and thin spots, particularly at corners and contact points, leading to premature failure.

The industry measures abrasion resistance through standardized tests like the Martindale abrasion test, which counts how many cycles of rubbing a material can withstand before showing visible wear. Premium backpack materials typically withstand 15,000+ cycles—approximately 3-5 years of regular professional use.

Tear resistance measures how well a material resists ripping when caught, snagged, or punctured. This property becomes critical when:

• Pulling your backpack from tight spaces

• Accidentally catching it on door handles or chair corners

• Overstuffing compartments with sharp-edged items

The Elmendorf tear test is the standard measurement method, with quality professional backpacks requiring materials that resist tearing even when already punctured or nicked.

Burst strength determines how much internal pressure a material can withstand before failing. This becomes especially important for professionals who:

• Carry heavy laptops and equipment

• Frequently overstuff their bags with documents

• Transport irregularly shaped items that create pressure points

Common weak points include bottom corners, handle attachments, and zipper junctions, where various types of leather types for durable bags show distinct advantages over some synthetic options.

Water and Weather Protection

For professionals carrying valuable electronics and important documents, water protection isn’t optional—it’s essential. When evaluating backpack materials, understanding the distinction between water-resistant and waterproof properties is critical:

• Water-resistant materials repel light moisture and brief exposure to rain but will eventually allow water penetration with sustained exposure

• Waterproof materials prevent water penetration even during extended exposure to heavy precipitation

Various protective coatings enhance a material’s natural water resistance:

| Coating Type | Protection Level | Durability | Common Applications |

|---|---|---|---|

| DWR (Durable Water Repellent) | Light-moderate | Needs reapplication | Most nylon/polyester bags |

| PU (Polyurethane) | Moderate-high | Good | Professional backpacks |

| TPU (Thermoplastic Polyurethane) | Very high | Excellent | Premium business bags |

| PVC (Polyvinyl Chloride) | Maximum | Very durable | Extreme weather protection |

Water protection is typically measured using hydrostatic head ratings, with 1,500mm providing basic protection against light rain, while 10,000mm withstands heavy downpours—crucial for protecting laptops and documents.

Beyond water, quality materials must also resist other environmental factors:

• UV radiation that causes fading and material degradation

• Temperature fluctuations that can crack or weaken materials

• Humidity that may promote mold or mildew growth

For professionals who regularly transition between indoor and outdoor environments, materials with essential features for waterproof leather backpacks provide necessary protection without sacrificing professional appearance.

Weight-to-Strength Ratio and Professional Comfort

The ideal professional backpack strikes a delicate balance between durability and weight. This weight-to-strength ratio directly impacts comfort during commuting and business travel, affecting posture, energy levels, and overall satisfaction with the bag.

When comparing equivalent strength materials, the weight differences can be substantial—1000D Cordura nylon typically weighs 30-40% more than 210D ripstop nylon of similar dimensions, yet may offer only marginally better protection for typical office use. For professionals who commute by foot or public transit, this added weight compounds daily fatigue.

Material selection should consider:

• Daily commute distance and method

• Typical contents weight (laptop, documents, accessories)

• Physical comfort requirements and existing back/shoulder issues

Materials that distribute weight properly across the back help maintain proper posture and reduce strain. Premium backpacks often incorporate even weight distribution features that work in harmony with the material properties to maximize comfort without sacrificing protection.

Aesthetics and Professional Appearance

In professional environments, your backpack is an extension of your personal brand. Material choice significantly influences how others perceive both you and your work. Beyond functional properties, material aesthetics convey important messages about attention to detail, quality standards, and professional identity.

Key aesthetic considerations include:

• Texture and finish that complement business attire

• Draping and structure that maintain shape even when not full

• Color retention and resistance to fading from UV exposure

• Appropriate material formality for specific work environments

Different professional contexts demand different material aesthetics—full-grain leather projects established authority in traditional corporate settings, while technical fabrics may better suit creative or technology-focused workplaces.

Premium Nylon Fabrics in Professional Backpacks

Understanding Denier Ratings and Professional Durability

When evaluating professional backpack materials, denier rating is one of the most important specifications to understand. Denier (D) measures the thickness of individual threads used in fabric construction—specifically, it’s the weight in grams of 9,000 meters of thread. Higher numbers indicate thicker threads and typically stronger materials.

For professional backpacks, common denier ratings include:

• 420D: Lightweight yet reasonably durable, suitable for light daily use

• 840D: Mid-range durability, appropriate for regular commuting

• 1000D: Heavy-duty protection, ideal for frequent travelers or rough handling

However, higher denier isn’t always better for professional contexts. While a 1000D backpack offers maximum durability, it typically weighs more and has a stiffer feel than lower denier alternatives. Many professionals find that 600-840D nylon provides the optimal balance between protection and comfortable carry for daily office use.

Material quality extends beyond mere thread thickness—weave pattern, coating technology, and manufacturing precision all contribute to the final performance. A well-constructed 600D nylon backpack often outperforms a poorly made 1000D bag in real-world professional use.

Ballistic Nylon: Superior Protection for Business Electronics

Originally developed during World War II for flak jackets, ballistic nylon has evolved into one of the premium materials for professional backpacks. Its distinctive 2×2 or 2×3 basket weave construction creates a dense, tight pattern that excels at resisting abrasion and punctures—ideal protection for valuable business electronics.

True ballistic nylon offers several advantages for professionals:

• Exceptional resistance to tears and abrasions

• Natural water resistance even before additional coatings

• Distinctive textured appearance that maintains professional aesthetics

• Excellent stability and structure that helps bags maintain shape

These properties make ballistic nylon particularly well-suited for professionals who:

• Travel frequently through airports and train stations

• Carry expensive laptops or electronic equipment

• Need bags that transition between client meetings and office settings

• Value long-term durability over minimal weight

The material’s main drawbacks include slightly higher weight compared to standard nylon and a somewhat stiffer feel, particularly when new. However, for protection of valuable business assets, many professionals find these trade-offs worthwhile when selecting from our leather work backpacks collection.

Cordura and Ripstop: Balancing Weight and Resilience

For professionals seeking lighter alternatives without significant durability compromise, Cordura and ripstop nylon offer compelling options.

Cordura is a branded, high-performance nylon known for its exceptional resistance to abrasions and tears. Compared to standard nylon of the same denier:

• Cordura typically offers 3-4 times greater abrasion resistance

• It maintains better color fastness under UV exposure

• The material generally has a softer hand feel while maintaining structure

Ripstop nylon features a distinctive grid pattern of reinforcement threads woven into the fabric at regular intervals. This construction:

• Prevents small tears from expanding into larger ones

• Adds minimal weight (typically 5-7%) for significant durability improvement

• Maintains flexibility and comfort against the body

Many modern professional backpacks incorporate both technologies—using Cordura with ripstop construction—to maximize protection while minimizing weight penalties. These materials excel for professionals who:

• Frequently transport their backpack between different environments

• Value weight reduction for comfort during long commutes

• Need moderate protection without the bulk of ballistic nylon

For environmentally conscious professionals, recycled nylon options (often labeled as “re-nylon” or similar terms) now provide comparable performance while reducing virgin plastic use.

Polyester and Alternative Synthetic Options

Polyester Strengths for Everyday Professional Use

While nylon often receives more attention in professional backpack discussions, quality polyester offers distinct advantages that make it ideal for certain professional applications. When comparing similar denier ratings:

• Polyester typically demonstrates 15-20% better UV resistance than nylon

• It maintains color vibrancy longer under regular sun exposure

• The material absorbs less water, drying more quickly after rain

• It generally costs 10-30% less than equivalent nylon

These properties make polyester particularly well-suited for professionals who:

• Work in sunny locations with high UV exposure

• Prioritize color consistency in their professional appearance

• Need quick-drying properties for variable weather conditions

• Seek value-oriented materials without significant performance compromise

For environmentally conscious professionals, recycled polyester (RPET) made from post-consumer plastic bottles offers comparable performance while reducing environmental impact. Many premium manufacturers now use RPET in mens leather laptop backpacks as lining materials, combining sustainability with professional aesthetics.

The primary drawback of polyester compared to nylon is somewhat lower abrasion resistance, making it less ideal for high-friction areas. However, for typical office commuting and business travel, quality polyester (especially in 600D+ weights) provides sufficient durability for most professionals.

Specialty Synthetics for Demanding Professional Environments

Beyond standard nylon and polyester, several specialty synthetic materials address specific professional needs where maximum performance justifies premium pricing.

X-Pac combines multiple layers of materials—typically a nylon or polyester outer face, polyester X-grid reinforcement, waterproof film, and inner scrim—creating an exceptionally durable, waterproof composite. For professionals facing extreme conditions or requiring maximum protection for sensitive equipment, X-Pac provides:

• Near-waterproof protection without additional coatings

• Exceptional tear strength with minimal weight penalty

• Distinctive technical appearance with visible reinforcement pattern

• Superior dimensional stability that maintains bag shape

Dyneema (formerly Cuben Fiber) offers the highest strength-to-weight ratio of any synthetic fabric. While less common in mainstream professional backpacks due to cost, Dyneema provides unmatched performance for ultralight business travel, with material weight approximately 40% lighter than equivalent-strength nylon.

For reinforcement at high-wear areas, materials like Hypalon (a synthetic rubber) provide targeted durability improvements at stress points like handles, bottoms, and attachment points. These specialty materials often complement primary fabrics in premium leather laptop backpacks, enhancing overall durability without adding significant weight.

Leather in Professional Backpacks: Premium Durability and Aesthetics

When it comes to professional backpacks that combine exceptional durability with distinguished aesthetics, leather stands apart from synthetic alternatives. Understanding leather grades is crucial for making an informed investment:

Full-grain leather represents the highest quality leather available, utilizing the entire top layer of the hide with its natural grain intact. This material:

• Develops a distinctive patina that enhances character over time

• Offers exceptional durability that can last decades with proper care

• Provides natural water resistance (especially when properly treated)

• Maintains a prestigious professional appearance appropriate for executive settings

Top-grain leather is created by sanding away imperfections from the upper layer of the hide. While still high quality, it:

• Typically has a more uniform appearance than full-grain

• Offers good durability but generally less than full-grain

• Is thinner and more pliable, often resulting in lighter backpacks

• Requires less maintenance while maintaining professional appearance

Genuine leather is made from the lower layers of the hide after the top portions have been removed. Despite the name, it represents the lowest quality of real leather:

• Lacks the durability and character development of higher grades

• Typically requires more chemical treatment to maintain appearance

• Generally has a shorter useful lifespan in professional environments

For professional use, full-grain and top-grain leathers offer the best balance of durability, appearance, and value. These premium materials feature prominently in office professional leather backpacks designed for business settings.

Leather backpacks do require more specific maintenance than synthetics, including:

• Regular conditioning to prevent drying and cracking

• Protection from prolonged direct sunlight to prevent fading

• Occasional waterproofing treatment for weather protection

However, these maintenance requirements are offset by leather’s unparalleled aging characteristics. Unlike synthetics that simply wear out, quality leather develops a unique patina—a burnished appearance that reflects its use history and often looks better with age. This characteristic makes full-grain leather backpacks particularly valuable for professionals seeking both longevity and evolving aesthetics.

Canvas and Hybrid Materials: Combining Tradition with Performance

Canvas offers professionals a distinctive alternative to both synthetic materials and leather, combining traditional aesthetics with practical functionality. In professional backpacks, waxed canvas is particularly valuable, featuring cotton fabric treated with paraffin or beeswax to enhance water resistance and durability.

Key advantages of waxed canvas for professional use include:

• Natural water repellency that improves with age and proper rewaxing

• Distinctive texture and appearance that develops character over time

• Excellent abrasion resistance suitable for daily commuting

• Environmentally friendly composition compared to many synthetics

The material does carry weight considerations—canvas typically weighs 30-40% more than synthetic alternatives of similar strength. However, many professionals accept this trade-off for the material’s unique aesthetic and environmental benefits, particularly in creative or less formal business environments.

Maintenance requirements include occasional rewaxing to maintain water resistance, typically needed every 1-2 years depending on use frequency and conditions. This process actually becomes part of the appeal for many owners, as each rewaxing enhances the material’s unique patina and character.

Hybrid materials represent an innovative approach to professional backpacks, combining the benefits of multiple materials. Common combinations include:

• Canvas bodies with leather reinforcements at stress points

• Synthetic panels with leather accents for reduced weight with premium aesthetics

• Weatherproof synthetics with canvas or leather on less exposed surfaces

These hybrid approaches allow manufacturers to place each material where its specific properties provide maximum benefit. For professionals seeking traditional styling with modern performance, vintage-style leather backpack materials often incorporate these thoughtful material combinations.

Beyond the Fabric: Critical Quality Indicators in Professional Backpacks

Construction Techniques and Hardware Quality

While material selection is fundamental to backpack quality, construction techniques and hardware choices are equally important indicators of overall durability and value. Even the finest materials will fail prematurely with poor construction.

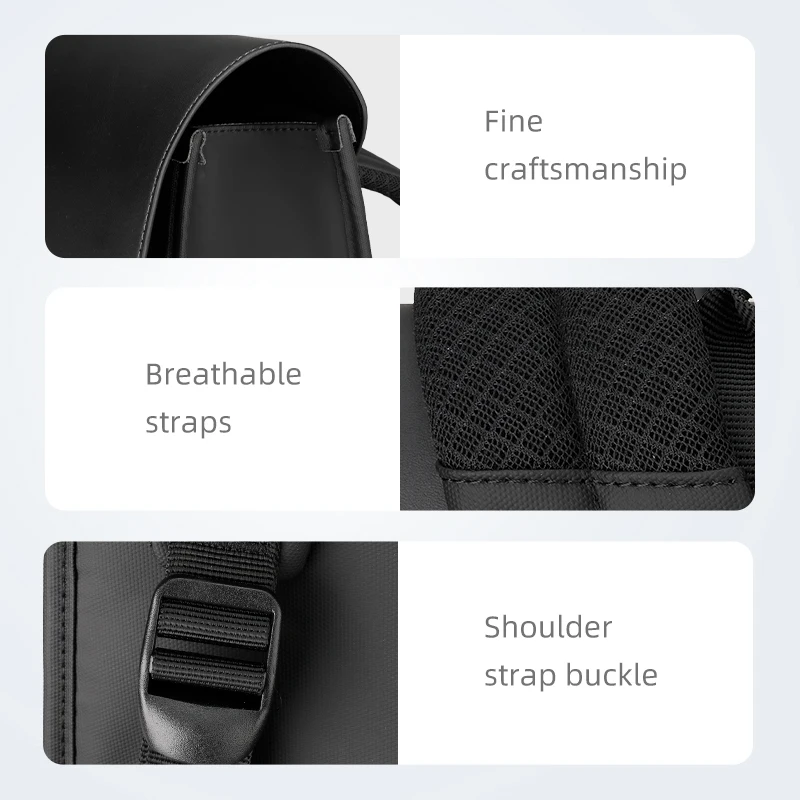

Quality professional backpacks utilize specific stitching techniques:

• Double-stitching at stress points and seams carrying significant weight

• Bar tacking (dense zigzag stitching) at areas of highest tension

• Binding (fabric wrapping) around edges to prevent fraying and wear

• Reinforced stitching patterns where straps connect to the main body

Hardware quality serves as an immediate indicator of overall backpack quality. Look specifically for:

• YKK zippers (particularly their water-resistant models for electronics compartments)

• Metal hardware instead of plastic at connection points and adjusters

• Reinforced zipper ends that prevent separation under stress

• Buckles and clasps that operate smoothly without catching

The relationship between material and construction is symbiotic—premium materials require sophisticated construction techniques to reach their full potential. In quality mens leather work backpacks, you’ll often find reinforced corners, stress point protection, and specialized stitching patterns that maximize material longevity.

Cost-cutting measures often appear first in hidden construction elements: single instead of double stitching, plastic hardware at stress points, or unreinforced zipper terminations. These compromises may not be immediately visible but significantly impact long-term durability.

Interior Linings and Weather Protection Systems

Professional backpack quality extends beyond exterior materials to interior linings and weather protection systems. These elements protect valuable contents and enhance overall functionality.

Quality interior linings serve multiple functions:

• Protect contents from abrasion against the interior surface

• Provide contrast for easier content visibility and organization

• Add structural support to maintain the bag’s shape when partially filled

• Create additional moisture barriers for electronics protection

The best professional backpacks feature interior linings specifically chosen to complement exterior materials—moisture-wicking materials for leather exteriors or ripstop nylon for maximum tear resistance in high-use compartments.

Weather protection systems vary considerably based on intended use:

• DWR (Durable Water Repellent) coatings provide basic protection against light rain

• PU (Polyurethane) coatings offer moderate-to-good water resistance

• TPU (Thermoplastic Polyurethane) lamination delivers excellent waterproofing

• PVC (Polyvinyl Chloride) coating provides maximum protection but added weight

For maximum electronics protection, seam sealing becomes essential. This process applies waterproof tape or sealant to interior seams, preventing water penetration through stitch holes. While invisible from the outside, this feature distinguishes truly weatherproof professional backpacks from those offering only basic water resistance.

For professionals who regularly transport valuable electronics between buildings or during commutes, leather briefcase backpacks with comprehensive weather protection systems provide necessary security without sacrificing professional appearance.

Choosing the Right Material for Your Professional Requirements

Urban Daily Commute: Balancing Aesthetics and Protection

The daily urban commuter faces specific challenges that directly influence material selection. Your backpack must transition seamlessly between public transportation, office environments, and potentially client meetings, all while protecting valuable equipment.

For typical urban commuting, consider these material priorities:

• Moderate abrasion resistance for daily handling and storage under desks

• Light-to-moderate weather protection for brief outdoor exposure

• Weight optimization for comfortable daily carrying

• Professional aesthetics appropriate for your workplace culture

Material recommendations based on commute scenarios:

For walking commutes under 30 minutes:

• Full-grain leather offers premium appearance with adequate protection

• 600-800D nylon or polyester provides lightweight durability

• Waxed canvas delivers distinctive style with good weather resistance

For public transit commutes with crowded conditions:

• Ballistic nylon resists abrasion from constant contact with other commuters

• Top-grain leather offers good durability with reduced weight compared to full-grain

• Cordura nylon provides excellent strength-to-weight ratio

For bicycle commutes or variable weather exposure:

• Waterproof-treated nylon with sealed seams offers maximum weather protection

• Technical synthetic blends provide lightweight performance

• Hybrid materials with waterproof components protect electronics compartments

Your daily carry items—typically including laptops, tablets, chargers, and documents—require different levels of protection based on their value and sensitivity. Understanding what daily carry essentials for professionals you transport helps determine the appropriate material durability and protection level for your specific needs.

Frequent Business Travel: Durability for Diverse Environments

Business travelers face unique material challenges: their backpacks must withstand varied environments, rough handling by others, and constant packing and unpacking cycles. For these demanding scenarios, material selection becomes especially critical.

Priority factors for business travel backpacks include:

• Enhanced durability for airport handling, security checkpoints, and overhead bins

• Comprehensive weather protection for unexpected exposure

• Scuff and abrasion resistance to maintain professional appearance

• Balanced weight for extended carrying through terminals

Material recommendations based on travel frequency:

For occasional business travelers (1-3 trips monthly):

• Full-grain leather offers excellent durability with distinguished appearance

• Ballistic nylon provides maximum protection with moderate weight

• Premium polyester (800D+) delivers good protection with lighter weight

For frequent travelers (weekly trips):

• Cordura nylon balances excellent durability with weight optimization

• Top-grain leather reduces weight while maintaining professional aesthetics

• Technical synthetics like X-Pac offer maximum protection for minimal weight

For international business travelers:

• Water-resistant materials with sealed seams protect against varied weather conditions

• Highly abrasion-resistant fabrics withstand rough handling in various transportation systems

• Lightweight options reduce burden during extended travel days

Security considerations also influence material choice—RFID-blocking pockets and cut-resistant materials provide additional protection for sensitive documents and devices, particularly valuable for international business travelers seeking to elevate their professional image with sleek leather bags.

14 Inch Leather Laptop Backpack, Brown Leather Backpack, Men's Leather Backpack, Vintage Leather Backpack

Price range: $177.28 through $199.12 Select options This product has multiple variants. The options may be chosen on the product pageDesigner Men's Backpack, Men's Leather Laptop Backpack, Men's Leather Work Backpack

Price range: $158.04 through $160.04 Select options This product has multiple variants. The options may be chosen on the product page15 Inch Leather Laptop Backpack, Leather Briefcase Backpack

$332.96 Select options This product has multiple variants. The options may be chosen on the product page17 Inch Leather Laptop Backpack, Men's Leather Travel Backpack, Men's Leather Work Backpack

Price range: $106.28 through $143.88 Select options This product has multiple variants. The options may be chosen on the product pageWomen's Leather Backpack, Women's Leather Work Backpack

Price range: $119.36 through $128.52 Select options This product has multiple variants. The options may be chosen on the product pageFull Grain Leather Backpack, Men's Leather Laptop Backpack, Men's Leather Work Backpack

$353.46 Select options This product has multiple variants. The options may be chosen on the product page

Maintaining Material Quality: Care and Longevity

The longevity of your professional backpack depends not only on initial material quality but also on proper maintenance. Different materials require specific care approaches to maintain their protective properties and professional appearance.

For leather backpacks:

• Apply conditioner every 3-6 months to prevent drying and cracking

• Clean spills promptly with appropriate leather cleaners

• Store in breathable dust bags when not in use for extended periods

• Keep away from direct heat sources and prolonged sun exposure

• Treat with leather protector to enhance water resistance

For nylon and polyester backpacks:

• Spot clean with mild soap and warm water

• Allow to air dry completely before storage

• Avoid machine washing unless specifically indicated by manufacturer

• Reapply DWR treatment annually if water resistance diminishes

• Check and clean zippers regularly to prevent failure

For canvas backpacks:

• Remove surface dirt with soft brush

• Clean spots with mild soap and cold water

• Allow to dry naturally away from direct heat

• Reapply wax coating when water stops beading on surface

Common damaging mistakes to avoid:

• Machine washing leather or waxed canvas

• Using harsh detergents on any professional backpack material

• Drying wet backpacks with direct heat (hair dryers, radiators)

• Storing in compressed or folded positions for extended periods

Professional backpacks represent a significant investment, and proper care substantially extends their useful life. For leather backpacks specifically, using appropriate leather care products for backpacks can extend lifespan from 3-5 years to 10+ years while maintaining professional appearance.

FAQs: Professional Backpack Material Questions

What denier rating is best for business use?

For most professional environments, 600-800D nylon or polyester provides an optimal balance between durability and weight. Higher ratings (1000D+) offer additional protection but with weight penalties, while lower ratings may not withstand daily professional use.

How waterproof should a professional backpack be?

At minimum, professional backpacks should resist light rain for 10-15 minutes—sufficient for moving between buildings or to transportation. For those regularly exposed to weather, look for waterproof ratings of 5000mm+ and sealed seams, especially in laptop compartments.

Are leather backpacks worth the investment?

Quality leather backpacks typically offer 2-3 times the lifespan of synthetic alternatives when properly maintained. Their ability to develop character while maintaining professional appearance makes them cost-effective long-term investments for many professionals, despite higher initial costs.

Can professional backpacks be machine washed?

Most professional backpacks should not be machine washed. Synthetic backpacks may allow gentle machine washing (check manufacturer instructions), while leather and canvas backpacks should always be spot-cleaned only. Machine washing typically damages waterproof coatings and structural elements.

How can I determine if a backpack’s materials are high-quality?

Look for specific material descriptions (e.g., “1000D Cordura nylon” rather than just “nylon”), YKK zippers, double stitching at seams, reinforced stress points, and clear identification of leather grade if applicable. Reputable manufacturers provide detailed material specifications.

Making an Informed Investment in Your Professional Backpack

Selecting the right material for your professional backpack requires balancing multiple factors: durability requirements, protection needs, weight considerations, and aesthetic preferences. By understanding the distinct properties of each material option, you can make an informed decision that aligns with your specific professional context.

Remember these key considerations when evaluating material quality:

• Match material durability to your actual usage patterns rather than simply choosing the most robust option

• Consider the weight implications of material choices for daily comfort

• Balance weather protection with your typical exposure conditions

• Select aesthetics appropriate for your professional environment

The intersection of material quality and construction techniques ultimately determines a professional backpack’s performance and longevity. Even the finest materials cannot overcome poor construction, while excellent construction cannot fully compensate for substandard materials.

For most professionals, the ideal backpack represents a carefully considered compromise—durable enough for daily use, protective enough for valuable contents, lightweight enough for comfortable carrying, and aesthetically appropriate for professional environments. By applying the material knowledge from this guide, you can confidently select a professional backpack that will serve as a reliable partner in your professional journey for years to come.